CasNo: 1592-23-0

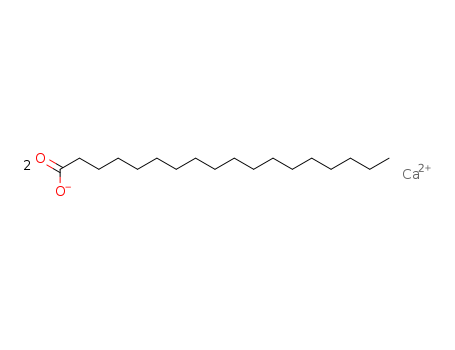

Molecular Formula: C36H70CaO4

Appearance: white solid

|

|

|

|

Composition |

Chemical Formula: Calcium stearate is represented by C36H70O4.Ca or C36H70CaO4. |

|

Application in Concrete |

Damp-proofing Admixture: Calcium stearate serves as a damp-proofing admixture in concrete to restrict water and aggressive ions' ingress. |

|

Lightweight Concrete |

Hydrophobic Properties: Calcium stearate is hydrophobic and can provide a water-repellent layer in lightweight concrete, reducing pore filling and cracking. |

|

Surfactant Properties |

Anionic Surfactant: Calcium stearate acts as an anionic surfactant in cement-based materials. |

|

Additional Benefits |

Corrosion Reduction: Calcium stearate significantly reduces corrosion attacks in concrete. |

|

Pyrolysis |

Hydrocarbon Generation: Pyrolysis of calcium stearate produces hydrocarbons, CO2, CaO, CaCO3, coke, and other inorganic compounds. |

|

Overview |

Calcium stearate also known as calcium octadecanoic acid. Light white crystalline powder. Chemical formula (C17H35COO) 2Ca. The molecular weight is 607.00. Melting point 179~180 ℃, decomposed by heat. Insoluble in water, cold ethanol and diethyl ether, soluble in hot benzene, toluene, and turpentine, slightly soluble in hot ethanol and diethyl ether. It reacts with strong acid to be decomposed into stearic acid and corresponding calcium salt. Water absorption in the air. Intolerance lipolytic microorganisms. Pyrolysis to generate stearin ketones and hydrocarbons. Non-toxic. Industrial often mixed with the corresponding oleate.As stabilizers and lubricants of polyvinyl chloride; as halogen absorbent of polyethylene and polypropylene; as lubricants of polyolefin fibers and molded products; as lubricant and release agent of phenolic, amino and other thermosetting plastics; as intensifier of lubricating grease; as waterproofing agent of waterproof fabric; etc. Food grade Calcium stearate serves as an anti-caking agent. Dilute soap is made by the reaction of melt stearic acid and sodium hydroxide, reacting with calcium chloride, and Calcium stearate is obtained . It can be used as heat stabilizer of polyvinyl chloride, it has excellent lubricity. Thermal stability performance is general, and is less than barium stearate, lead stearate, tin stearate and cadmium stearate. But it is cheap, low toxicity, good processability. Combined with Zinc soap and an epoxy compound, it shows a synergistic effect, improving the thermal stability, and it is commonly used for requirements nontoxic soft products, such as food packaging films, medical instruments, etc. It combines with the base lead salts and lead soaps used for hard products, increasing the gelation speed. Calcium stearate is used for polyethylene and polypropylene, and it can eliminate the adverse effects of residual catalyst on the resin color and stability. This product is also widely used as lubricant and release agent of thermosetting plastics, such as polyolefin, polyester reinforced plastics, phenolic resin, amino resin, etc. The disadvantage of Calcium stearate is initial color. When heating at above 100 ℃ with longer time, Calcium stearate will make the white PVC become a reddish color. Particularly when titanium dioxide exists in formula, coloring is particularly serious. At this point, if 0.06~0.12% Na2CO3 or 0.09~0.19 NaHCO3 are added, it can overcome this shortcoming. But because these substances are too alkaline, they are not used in practice. In addition, when the amount of this product is large, there is segregation scaling phenomenon. |

|

chemical properties |

Calcium stearate is an odorless, white powder, Insoluble in water, slightly soluble in hot ethanol. It used in many manufacturing processes and preparations. Also known as calcium salt and octadecanoic acid, it is a carboxylate created by heating stearic acid and calcium oxide.Calcium stearate has many potential uses, including as a flow agent, stabilizing agent and surface conditioner in the production of certain foods — notably, many candies. It is used as a mold-release agent for pharmaceutical tablets and capsules, as an anti-caking agent in cosmetics and as a thickener in lubricants and greases. It is also a stabilizer found in many plastics and is used to process concrete and paper. |

|

Barium stearate |

Barium stearate, also known as " barium octadecanoic acid ", chemical formula Ba (C18H35O2) 2. The molecular weight is 704.13. White fine powder. Melting point 160 ℃, relative density of 1.15. Insoluble in water, soluble in cold ethanol, soluble in hot ethanol, benzene, toluene, and other non-polar solvents, after heated and dissolved in an organic solvent , and cooled into jelly. Encountered strong acid, Barium stearate can be decomposed into stearic acid and corresponding barium salt. Water absorption in the air.Preparation method: Stearic acid reacts with barium carbonate or barium hydroxide, or sodium stearate solution reacts with dilute barium chloride solution, Barium stearate is obtained . Barium stearate can be used as waterproof products, alkali pump packing, and can also be used as high-temperature lubricants and fillers of machine; heat resistance and light fastness of stabilizers of polyvinyl chloride plastics, high temperature resistant powder mold of rubber products. Barium stearate is toxic, toxicity coefficient T = 2, the typical symptoms of poisoning are vomiting, abdominal pain, diarrhea, increased blood pressure, pulse rate disorders, etc. |

|

Anti-caking agent |

Anti-caking agent, also known as caking inhibitor, is used to prevent the particles and powdered food from aggregation and agglomeration, maintaining its loose or free flowing substances. Its particles is tiny, loose porous and strong adsorption. It easily absorbs the water and oil which lead to the formation of agglomerates, making food to maintain a powder or granules state. There are five species of anti-caking agent which are permitted to be used in China: potassium ferrocyanide, sodium aluminosilicate, tricalcium phosphate, silica and microcrystalline cellulose. Anti-caking agents are varied, in addition to five kinds which are permitted in China, aluminum, silica, calcium silicate, Calcium stearate, magnesium carbonate, magnesium stearate, magnesium, magnesium phosphate, magnesium silicate, kaolin, talc and ferrocyanide are permitted to be used in Foreign. In addition, they have anti-caking effect, and some also have other effects, for example, calcium silicate and kaolin also has the function of filter aids, and Calcium stearate and magnesium stearate have emulsifying effect. And in addition that ferrocyanide has limited ADI value, security of other varieties are very good, ADI values are no provisions. Based on requirement, proper developments are still needed. |

|

Wire drawing lubricants |

During the process of the metal wire drawing, it sever as technological lubrication material. Its role is to form a lubricant film between the drawing metal and wire drawing die wall, reducing friction of interface, and preventing metal from bonding with wall because of heat, so as to reduce energy consumption and temperature when wire drawing, extend the service life of the die, ensure the surface quality of the product and make deformation uniform. Steel wire drawing lubricants are classified into solid and liquid lubricants. Solid lubricant is powder lubricant, used for dry wire drawing. Its constitution is a variety of single metal soap or metal soap which is added certain additives. Metal soap is a metal salt of fatty acids. Metallic soap as a lubricant is required to have a higher softening point and transition temperature (coefficient of friction is a sudden rise in temperature), good wear resistance and pressure resistance. Metal soap used as drawing lubricants commonly are sodium soaps and calcium soap. Sodium soda and sodium soaps are sodium stearate C17H35COONa which is chemical combination of caustic soda and saturated fatty acid glycerol C3H5 (C17H35COO), is water-soluble soap and easy to remove, applying to not too high speed and temperature of dry wire drawing. It can also be used to wet wire drawing of filament, or for drawing of steel wire with subsequent plated operations. Calcium soaps are Calcium stearate which are chemical combination of calcium hydroxide or calcium oxide and glyceryl stearate. Others include barium stearate, zinc stearate, aluminum stearate and other metal soaps. Calcium soap can form thick lubricating film with good elongation and lubrication, and therefore often it is the main component of the solid lubricant. Calcium soap is insoluble in water, easily washed clear, not applying to drawing of pre-coated steel wire. Additives are to improve lubricity or to obtain special properties which are small amounts of other substances added in the lubricant, including extreme pressure additives, oiliness improving agents, thickeners and preservatives, etc. Extreme pressure additives serve as the main additives. It can react with the metal friction surface to generate high melting point and low shear strength of metallic compound thin film, thereby improving the lubrication performance of the lubricant at high temperature and pressure. Such additives mainly include molybdenum disulfide, graphite and poly tetra fluoro ethylene, etc. Oily improving agent, also known as active additive, its role is to improve the capability of lubricants to absorb and form lubricating film. Such additives include various higher fatty acids, tallow amine, etc. Thickener is an added additive to increase the consistency of lubricant, whose materials include soda ash, lime, barium sulfate, calcium carbonate, etc. Preservatives, also known as corrosion inhibitor ,its role is to prevent corrosion of steel wire substrate from lubricant,whose material include sodium nitrite, sodium phosphate, etc. The above information is edited by the lookchem of Liu Yujie. |

|

Identification test |

Taking 1 g sample, mixed with 25ml and 5ml hydrochloric acid water, heating, fatty acids are released, so that oily layer floats in the surface of the liquid. Water layer is used for calcium test (IT-10), and it should be positive. Taking 25 g sample, mixed with 200 ml hot water, added sulfuric acid test solution (TS-241) 60ml, heating and vigorous stirring to precipitate fatty acid, there is clear liquid. Fatty washed with boiling water, until the sulfates is divisible, collected in a small beaker, warmed on a steam bath to completely separate the fatty acid from the aqueous layer, and kept clear. Cooled and discarded the aqueous layer, the fatty acid melted and filtered-dried beaker, dried at 105 ℃ for 20min. The freezing point of purified fatty acid should not be less than 54 ℃. Freezing point is determined by conventional methods. |

|

Content analysis |

About 1.2 g sample is accurately weighed, added 0.1 mol/L hydrochloric acid, boiled 10min, or until the fatty layer is clear, if necessary, adding water to maintain the original volume. Cooled and filtered, the filtrate and flask was washed thoroughly with water until last washing liquor is no longer acidic to litmus. Filtrate is treated with sodium hydroxide solution (TS-224.) and it is neutral to litmus. Under sufficiently stirred with a magnetic stirrer, about 30ml 0.05mol/L disodium EDTA is added via a 50ml burette, adding 15ml sodium hydroxide solution and 300 mg hydroxy naphthol blue indicator, and continuing the titration to a blue endpoint. Per milliliter 0.05mol/L disodium EDTA is equivalent 2.804 mg CaO. |

|

Toxicity |

ADI unrestrictive provision (FAO/WHO,2001). GRAS(FDA,§184.1229, 2000). |

|

Limitation of utilization |

FAO/WHO (1984): coated with glucose powder, sucrose powder and stock cube, etc. 15g/kg. GB 2760-1996: chewing gum base, GMP limit. In USA, it is used for beet sugar, pressed candies, garlic salt, meat tenderizer, dry molasses, salad prefabricated powder, spice powder, yeast. |

|

Production methods |

Firstly melted stearic acid reacts with sodium hydroxide solution to form a dilute soap, then reacted with calcium chloride, Calcium stearate crude is obtained, followed by washed, swirling water, drying, finished product is obtained. Kg/ton stearate, 920 sodium hydroxide (100% discount) 140 Calcium chloride (100% discount) 400. After food grade sodium stearate interacts with calcium chloride solution, follow by filtered and refined. |

|

Category |

Toxic substance |

|

Acute toxicity |

Oral-rat LD50:> 10000 mg/kg; Oral-mouse LD50:> 10000 mg/kg. |

|

Flammability hazard characteristics |

A public dust hazard; acrid smoke is generated by thermal decomposition. |

|

Storage Characteristics |

Storehouse keeps low temperature, dry and ventilated. |

|

Extinguishing agent |

Water |

|

Occupational standards |

TWA 10 mg/m3 |

|

Production Methods |

Calcium stearate is prepared by the reaction of calcium chloride with a mixture of the sodium salts of stearic and palmitic acids. The calcium stearate formed is collected and washed with water to remove any sodium chloride. |

|

Application |

Calcium stearate is used as a flow agent in powders including some foods (such as Smarties), a surface conditioner in hard candies such as Sprees, a waterproofing agent for fabrics, a lubricant in pencils and crayons. The concrete industry uses calcium stearate for efflorescence control of cementitious products used in the production of concrete masonry units i.e. paver and block, as well as waterproofing. In paper production, calcium stearate is used as a lubricant to provide good gloss, preventing dusting and fold cracking in paper and paperboard making. In plastics, it can act as an acid scavenger or neutralizer at concentrations up to 1000ppm, a lubricant and a release agent. It may be used in plastic colorant concentrates to improve pigment wetting. In rigid PVC, it can accelerate fusion, improve flow, and reduce die swell. Applications in the personal care and pharmaceutical industry include tablet mold release, anti-tack agent, and gelling agent. Calcium stearate is a component in some types of defoamers. |

|

Preparation |

Calcium stearate is produced by heating stearic acid, a fatty acid, and calcium oxide:2C17H35COOH + CaO→(C17H35COO)2Ca + H2OIt is also the main component of soap scum, a white solid that forms when soap is mixed with hard water. Unlike soaps containing sodium and potassium, calcium stearate is insoluble in water and does not lather well . Commercially it is sold as a 50 % dispersion in water or as a spray dried powder. As a food additive it is known by the generic E number E470. . |

|

Definition |

Variable proportions of calcium stearate and calcium palmitate. |

|

Hazard |

A nuisance dust. |

|

Flammability and Explosibility |

Notclassified |

|

Pharmaceutical Applications |

Calcium stearate is primarily used in pharmaceutical formulations as a lubricant in tablet and capsule manufacture at concentrations up to 1.0% w/w. Although it has good antiadherent and lubricant properties, calcium stearate has poor glidant properties. Calcium stearate is also employed as an emulsifier, stabilizing agent, and suspending agent, and is also used in cosmetics and food products. |

|

Safety Profile |

A nuisance dust. When heated to decomposition it emits acrid smoke and irritating fumes. |

|

Safety |

Calcium stearate is used in oral pharmaceutical formulations and is generally regarded as a relatively nontoxic and nonirritant material. |

|

storage |

Calcium stearate is stable and should be stored in a well-closed container in a cool, dry place. |

|

Regulatory Status |

GRAS listed. Included in the FDA Inactive Ingredients Database (oral capsules and tablets). Included in nonparenteral medicines licensed in the UK. Included in the Canadian List of Acceptable Non-medicinal Ingredients. |

InChI:InChI=1/C18H36O2.Ca/c1-2-3-4-5-6-7-8-9-10-11-12-13-14-15-16-17-18(19)20;/h2-17H2,1H3,(H,19,20);/q;+2/p-1

The equilibrium solubilities of two mode...

Dissolution of calcium salt of a long ch...

The invention relates to a continuous pr...

The invention belongs to the technical f...

This work introduces the complementary u...

stearic acid

calcium stearate

| Conditions | Yield |

|---|---|

|

With water; calcium oxide; In glycerol;

|

|

|

With Ca2H2O; In ethanol;

|

|

|

With calcium hydroxide; In ethanol; water; for 24h; pH=5.9;

|

|

|

With calcium hydroxide; at 70 - 150 ℃; for 1h; under 2250.23 Torr; Pressure; Temperature; Autoclave;

|

|

|

With calcium hydroxide; In methanol; water; at 65 ℃; for 0.00138889h; Industrial scale;

|

calcium(II) chloride dihydrate

stearic acid

calcium stearate

| Conditions | Yield |

|---|---|

|

In water; at 70 ℃;

|

stearic acid

calcium oleate